Ear Impression Techniques for Earmolds and Earshells: In the realm of audiology and hearing aid fabrication, the Ear Impression Technique stands as a pivotal process, intricately weaving together precision and meticulous attention. This method initiates with a detailed examination of the ear canal using otoscopic tools, underscoring the importance of identifying abnormalities and cerumen levels. The subsequent steps unfold a carefully choreographed sequence, involving the insertion of a canal block to control impression material flow, precise mixing of materials, and the methodical filling of the ear.

This comprehensive guide navigates through crucial aspects such as marking, curing time, and the delicate removal process, concluding with inspection, annotation, and measures for shipping or digital transmission. The narrative underscores the paramount significance of detail-oriented practices and strict adherence to recommended protocols throughout this specialized procedure. From examining the ear canal to the intricate steps of impression material mixing and application, this article unfolds the nuanced artistry behind the Ear Impression Technique, shaping the foundation for the creation of bespoke hearing aids tailored to the unique contours of each individual’s ear.

Table of Contents |

|

Ear Impression Technique

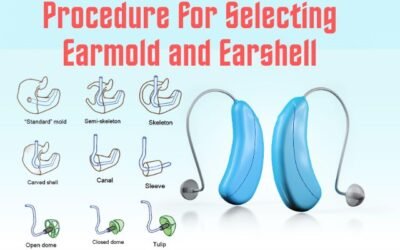

Introducing the intricate process of the ear impression technique. Ear impression techniques also depend upon the Types of Earmold or Earshell. This method begins with a meticulous examination of the ear canal using otoscopic tools. The initial step emphasizes the importance of identifying abnormalities and cerumen levels before proceeding. Subsequent steps involve inserting a canal block to control the flow of impression material, mixing the material with precision, and carefully filling the ear. This comprehensive guide details crucial aspects such as marking, waiting for adequate curing, and the delicate removal process, concluding with inspection, annotation, and appropriate measures for shipping or digital transmission. Attention to detail and adherence to recommended protocols are paramount throughout this specialized procedure.

Step 1: Examine the ear canal

Initiating the ear impression process commences with an otoscopic examination. It is crucial to retract the pinna, enabling a clear view of the eardrum and canal walls to identify any abnormalities before proceeding with the impression.

- Avoid continuing if there is a significant amount of cerumen present, as it may compromise the accuracy of the ear impression. The tolerance for cerumen varies depending on the required precision. For instance, a low-gain, vented, BTE earmold or full concha ITE hearing aid may tolerate more cerumen compared to a high-gain occluded aid or a CIC.

- Do not proceed if any visible signs of outer or middle ear infection or inflammation exist, or if there is a distended or perforated eardrum. In such cases, obtaining medical clearance is essential before proceeding.

- Exercise caution when making a deep impression if the ear canal widens substantially, as it may pose difficulties during removal. It is common for ear canals to slightly widen in the anterior-posterior dimension just medial to the second bend. Extreme cases, such as post-mastoidectomy, require ENT clearance before taking an impression. In such situations, additional blocks are used to pack the surgically created cavity before inserting the block that protects the eardrum.

- Trim any long hair in the concha with scissors to minimize distortion or difficulty in removing the impression.

Step 2: Insert a canal block

A canal block, also known as an oto-block, impression pad, or eardam, is a small amount of cotton wool or foam placed in the cross-section of the ear canal. Its purpose is to prevent impression material from flowing excessively into the canal. The block, resistant to flow, allows the impression material to uniformly fill the canal cross-section down to the desired length, avoiding uneven tapering. Typically, a strong thread is knotted around the block for easy removal, although this is often necessary only when removing the block without taking an impression.

Alternatively, the cotton or foam can be affixed to a tube. Canal blocks are available in various sizes with pre-tied thread, and choosing the correct size is crucial. Blocks that are too small might be pushed down by the impression material, while overly large blocks may not insert far enough and can be uncomfortable. Special blocks with reduced thickness in the medial-lateral dimension are designed for deep canal impressions.

Inserting the block is conveniently done with an illuminated plastic stick, often referred to as an earlight, oto-light, or light-stick. It’s essential to brace your little finger against the side of the head when using the earlight. If inserting the cotton block suddenly becomes easier, caution is advised, as the canal may widen unexpectedly, making impression removal challenging.

The depth of insertion for the canal block is crucial. While earmold or aid manufacturers can create the finished device with a canal stalk shorter than the impression, they cannot extend it. It is recommended to err on the longer side when determining the needed length. Ideally, the block should be at or beyond the second bend, unless a very short canal stalk is specifically required for the finished device. If a shorter earmold or shell is desired, the desired length can be marked on the impression.

Step 3: Mix the Impression Material

Adhere strictly to the recommended proportions of the ingredients. Modifying the mixture may alter its viscosity, making it more fluid for easier syringing or adjusting the setting time. However, such alterations could potentially have a detrimental impact on the final impression. For instance, an excess of liquid in a liquid/powder acrylic mixture may cause the impression to melt or deform more readily under heat and increase shrinkage.

Thorough and rapid mixing is essential. Use a spatula on a disposable pad or a surface that can be easily cleaned. This precautionary measure aims to prevent:

- Potential adverse health effects for the clinician resulting from the repeated absorption of impression chemicals through the skin.

- Contamination of the impression material with sulfur-based substances that may seep from hand lotions and latex gloves.

- Elevation of the temperature of the impression material, as setting time diminishes with increasing temperature.

Similarly, the impression material can be transferred into the syringe using the spatula or by maneuvering the inverted syringe at an angle around the mixing pad.

Step 4: Fill the Ear

- Partially depress the syringe or gun until material begins to flow from the tip.

- Lift and pull back the pinna to allow the syringe to be inserted as deeply as possible.

- Use syringe extension tips for long and narrow canals.

- Depress the syringe until the material covers the tip to a depth of approximately 6 mm (0.25 inches).

- Continue depressing the syringe plunger while simultaneously withdrawing the syringe tip to maintain a consistent depth.

- Once the canal is filled and the concha is nearly filled, lower the plunger end and move the syringe tip along the back of the concha towards the helix.

- Fill the cymbal-concha, then raise the plunger end and move the syringe tip down the front part of the cavum-concha near the tragus.

- Complete the syringing process when the concha is fully filled and slightly overflowing on all sides.

- The earmold/earshell laboratory needs to recognize ear landmarks, achievable by over-filling the concha.

- Ensure a continuous motion with constant pressure on the syringe for the entire operation.

- Finish with a nearly flat external surface for easy gluing of the impression to a container for potential shipping needs.

Step 5: Mark the Impression

If the hearing aid is an In-the-Ear (ITE) or In-the-Canal (ITC) type and is equipped with a directional microphone, mark a horizontal line on the impression’s surface. This marking will help the manufacturer align the two ports on the same horizontal plane, optimizing frontal directivity.

Step 6: Wait

Evaluate the hardness of the impression after 7 to 10 minutes, varying with the impression material and temperature. Use a fingernail or another sharp object to briefly indent the impression. If the indent completely disappears, the impression is adequately cured. In case of intricate or lengthy canals, extend the waiting time slightly beyond the usual duration to minimize the risk of tearing during extraction.

Step 7: Remove the Impression and Inspect the Ear

Instruct the patient to move their jaw several times and manipulate the pinna by pulling down, then back, and finally up. These actions are intended to loosen the connection between the ear impression and the ear itself. Remove the helix portion of the impression, known as the helix lock. Hold the impression securely and gently twist and pull it out, adapting the motion to suit the unique characteristics of the individual’s ear. Carefully examine the ear to ensure that no residue is left behind.

Step 8: Inspect the Impression

Ensure there are no creases, spaces, or air pockets. While imperfections in certain areas that will be removed during the final product’s production are acceptable, they should not be present elsewhere. The quality of the canal stalk is crucial, and if uncertain, create a second impression. Keep the canal block connected to the impression, as its orientation provides the manufacturer with insights into the canal’s direction toward the end of the impression material. Never hesitate to take an additional impression if needed.

Step 9: Annotate and send the impression

Prepare the finalized impression for shipping by securing it in a shipping container in a manner appropriate for the impression material. Any distortion occurring during transportation may be replicated in the final product. Alternatively, utilize a laser scanner to capture the impression digitally and transmit the scanned image to the manufacturer electronically. Regardless of the method chosen, provide annotations detailing any abnormalities observed in the ear canal or specific requests for differences in the final otoplastic compared to the impression. Identify any indentations in the impression caused by bumps in the ear, as failure to do so may lead the technician to assume they result from a flawed impression technique and fill them. If the ear canal exhibits notable mobility during jaw movement, mark the mobile region unless the impression was taken with the jaw open.

Step 10: Clean up

Implementing proper infection control measures is crucial, not only for real-ear gain measurement, but delving into the specific level of risk and the corresponding type of control measures falls outside the purview of this book. While cerumen itself may not inherently pose an infectious threat, visually discerning the presence of blood or other fluids mixed with it proves challenging. Consequently, it is advisable to treat all cerumen as potentially infectious. In instances where ear infections are apparent or any procedure inadvertently results in bleeding within the ear canal, exercising extreme care and meticulous disinfection (or disposal) of equipment becomes imperative.

Additional CIC Hearing Aid Impression Technique

1. Extend the impression 5 mm beyond the second bend.

2. Choose a silicone impression material with medium-to-high viscosity, such as Otoform A/K, Westone, Silicast, Steramold, Otosil, or Dahlberg.

3. Utilize an open-jaw technique for the impression.

Ear Impression Materials

Ear impressions involve the use of at least three different materials, each requiring a chemical reaction to set when two components are mixed:

- Acrylic material (e.g., ethyl-methacrylate) involves combining a liquid and a powder, as seen in Audalin™.

- Condensation-cured silicone material (e.g., dimethyl-siloxane) requires the mixing of two pastes. Examples include Otoform-K™, Siliclone™, Blue Silicast™, and Micro-sil™.

- Addition-cured silicone material (e.g., polyvinylsiloxane, vinyl-polysiloxane) involves combining two pastes. Examples in this category are Otoform A/K™, Reprosil™, Pink Silicast™, Silasoft™, Mega-Sil™, Dur-a-sil Equal™, Matrics™, and Silhouette Plus™.

For ear impressions to result in a well-fitting yet comfortable earmold or earshell, the materials used must possess specific combinations of properties.

Conclusion

In conclusion, the ear impression technique is a meticulous and multifaceted process that demands precision and adherence to a series of crucial steps. The initial examination of the ear canal sets the foundation for a successful impression, emphasizing the identification of abnormalities and appropriate cerumen levels. The insertion of a canal block serves as a pivotal step, preventing excess material flow and ensuring uniform filling of the ear canal. The subsequent stages, from mixing the impression material with care to the delicate process of filling and marking, all contribute to the overall success of the procedure.

Furthermore, the importance of attention to detail is highlighted throughout the article, underscoring the significance of adhering to recommended protocols and guidelines. The concluding steps involve thorough inspection, annotation, and appropriate measures for shipping or digital transmission, emphasizing the need for a flawless and accurate ear impression. Overall, this comprehensive guide underscores the intricate nature of the ear impression technique, emphasizing the crucial role it plays in achieving well-fitting and comfortable earmolds or earshells for individuals with hearing aids.

FAQs about Ear Impression Techniques for Earmolds and Earshells

1. Why is it important to examine the ear canal before proceeding with the ear impression technique?

Answer: The examination of the ear canal is crucial to identify any abnormalities, cerumen levels, or signs of infection. This ensures accurate impressions and prevents complications during the process. Avoidance of proceeding in the presence of cerumen or infections is emphasized to maintain precision.

2. What precautions should be taken when inserting a canal block during the ear impression process?

Answer: When inserting a canal block, ensure it is resistant to flow and properly sized. Use caution if insertion becomes suddenly easier, as the canal may widen unexpectedly. The depth of insertion is crucial, and blocks should ideally extend to or beyond the second bend. Special blocks are recommended for deep canal impressions, and caution is advised in post-mastoidectomy cases.

3. Why is the correct mixing of impression material crucial, and what precautions should be taken during this step?

Answer: Correct mixing is essential for the viscosity and setting time of the impression material. Modifying the mixture can impact the final impression negatively. Precautions include adhering strictly to recommended proportions, avoiding contamination from sulfur-based substances, and preventing elevation of material temperature during mixing.

4. How should the ear be filled during the ear impression process, and why is it important to mark the impression for certain hearing aids?

Answer: The ear should be filled using a syringe, and constant motion with consistent pressure is essential for uniform filling. Marking the impression is crucial for In-the-Ear (ITE) or In-the-Canal (ITC) hearing aids with directional microphones, optimizing frontal directivity by aligning ports on the same horizontal plane.

5. What steps should be taken after removing the ear impression, and how should the finalized impression be prepared for shipping or digital transmission?

Answer: After removal, inspect the ear for residue and the impression for imperfections. Prepare the finalized impression for shipping by securing it appropriately or use a laser scanner for digital transmission. Annotate any abnormalities and provide specific requests. Cleaning up involves meticulous infection control measures, especially in cases of bleeding or visible ear infections during the procedure.

References:

- Hearing Aids – Harvey Dillon (Book)

- Essentials of Audiology – Stanley A. Gelfand, PhD (Book)

Thanks for sending audio materials too I is very needfull